Over 46 years of Innovation and Commitment

14,000 Machines • 27,000 Molds

The right solution to meet your production needs

Nissei ASB Machine Co., Ltd. (ASB) has been at the forefront of PET container machine and mold production technology since the 1970s. Our commitment to innovation and extensive knowledge has aided the evolution of PET bottles. This ensures that products are not only packaged attractively and fit for function, but also safe for society. In 1978, recognizing the need to better serve our customers and address the growing PET container industry, Nissei ASB Company was established to support the North American market. Now strategically located in Atlanta, Georgia, just 20 minutes away from the world's busiest airport, our North American Technical Support Center is well-positioned to meet the demands of the market. Our dedicated commercial team is ready to assist you throughout the entire project life cycle. Supporting your endeavor through each developmental stage, they will meticulously evaluate your present and future business requirements, presenting a versatile ASB solution customized to meet your specific needs. Our dedication and responsibility extend beyond this, as we aim to consistently support and deliver trusted technology that will stand as a valuable asset to your business for years to come.

Mold and Product Design + Inspection Capabilities

The container and mold design group seamlessly transforms your concept from its initial stages to the final product drawing for mold manufacturing.

Our design team, comprised of highly experienced professionals, is well equipped to provide guidance on design optimization and assist in creating a new design aligned with your vision. Guided by SPI industry standards and learned complexities from years of molding, our team is enabled with the experience required for success.

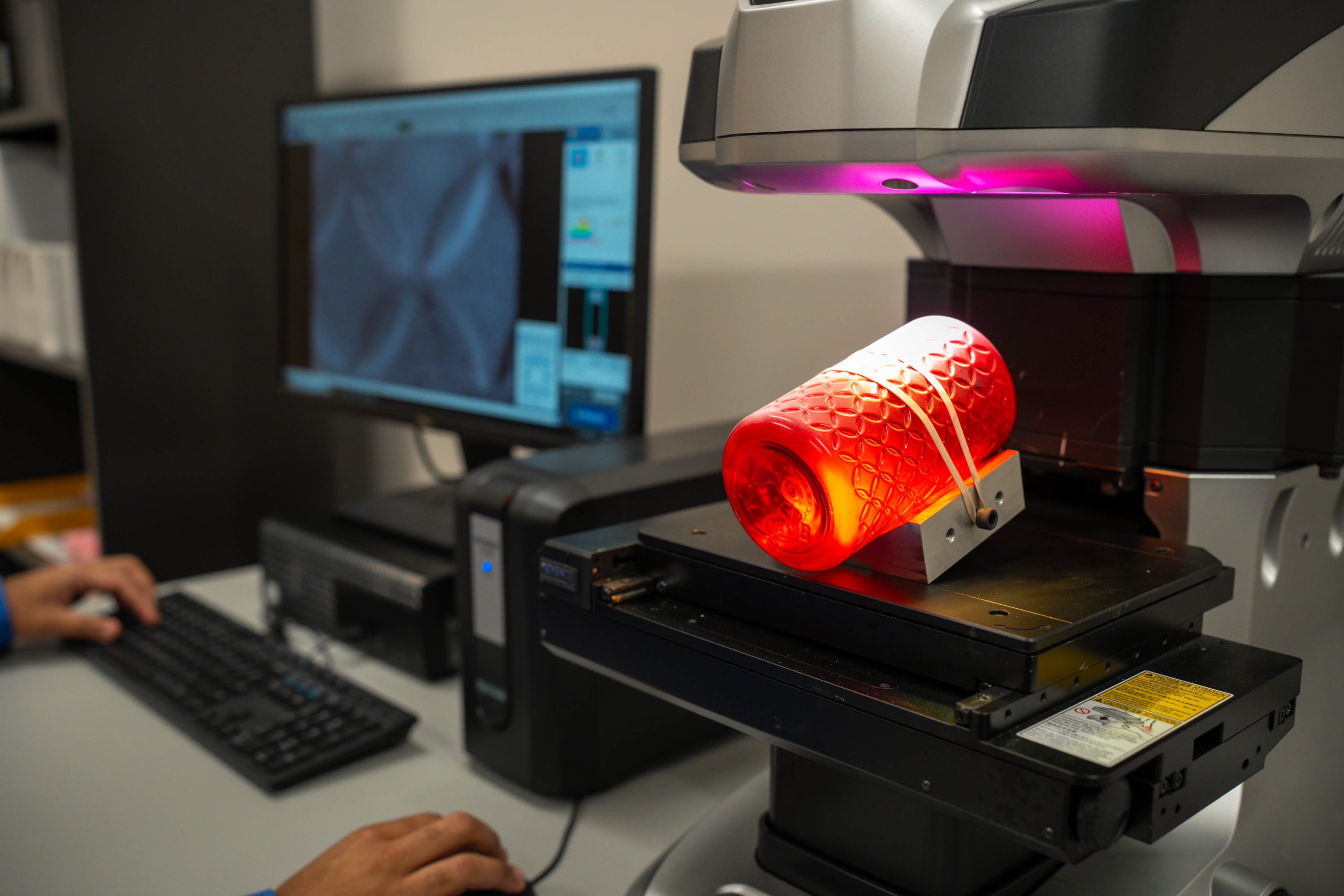

3D scanner capabilities enable accurate measurement and analysis of complex designs. After the final product drawing is completed, a full-size 3D model can be provided of your design. This benefit allows you to quickly confirm product design, fit, form and function.

Capabilities

- - Feasibility Study

- - CAD Design

- - 3D Prototyping

- - 3D Scanning

- - Profile Measurement

- - Light Weighting

- - Glass-to-Plastic Conversion

- - FEA Evaluation

- - Mold Interchangeability

- - Mold Design

Inspecting Capabilities

- - Contracing

- - Gawis Dimension Measuring

- - Visual Comparator Measuring

- - Magna Mike Wall Thickness Gauging

- - Stability Testing

- - Section Weight Testing

- - Vacuum Testing

- - Top Load Testing

- - Torque Testing

- - Drop Load Testing

- - Topwave Light Polarizing

Custom Shapes and Ideas are Brought to Life

Whether the design is simple or complex, we work to ensure your vision can be formed into the high-quality product that you imagined. Superior quality and longevity are key factors to our engineered solution. Each part of our molds are manufactured from the best globally sourced materials to provide an optimized combination of performance, strength, and durability. This method yields consistent production throughout the lifespan of the mold. Our production department is focused on supporting the tooling needs of the US and Canadian markets by providing overhauls, emergency spare parts, and modifications. This approach benefits our customers with a local source, clear communication, and a quick turnaround.

Machining Centers

• 5 axis Turn Mill • 5 axis High Speed Mill • EDM Sinker • Surface Grinder • Laser Engraving • Laser Welding • Conventional Mill • Conventional Lathe • IEPCO Treatment

Capabilities

• Unit Cavity • Development and Testing • Sampling • Audit and Repair • Spare Parts • Mold Modification • Tool Overhauls • CMM Inspection

Services Offered

• Machine Commissioning

• Mold Commissioning

• Machine Audits

• Trouble shooting

• Remote Diagnostics

• Infrastructure and plant layout

Recognizing the adverse effects of asset downtime on your business, our primary objective is to deliver unparalleled aftermarket support. Factory-trained service engineers ensure optimal performance and uptime for our customers. Whether it involves commissioning new machines or molds, conducting on-site machine audits, or optimizing the molding process and machine efficiencies, we are here to support your production and service needs.

Expansive Parts Inventory to Support Your Assets

Thanks to our robust inventory of spare parts, we ensure swift delivery, minimizing any downtime you may experience. Utilizing our innovative ASB Connect digital platform, we empower customers with flexible options phone or web based to order parts tailored to their requirements. The platform’s features include a comprehensive 360-degree view of parts, real-time stock levels, and pricing information. This feature provides enhanced transparency and support for our customers.

Theoretical and Practical Training for the future